Cost-effective blasting of sheet metal parts

The EUROBLECH trade fair will take place in Hanover from 22 to 25 October 2024. AGTOS will be showcasing the latest solutions in wheel blasting technology. Various concepts for processing metal parts of all kinds will be on display. This is because blasting technology is used for derusting, deburring, finishing, roughening and hardening surfaces. AGTOS wheel blasting systems offer many advantages in terms of cost-effective operation and maintenance.

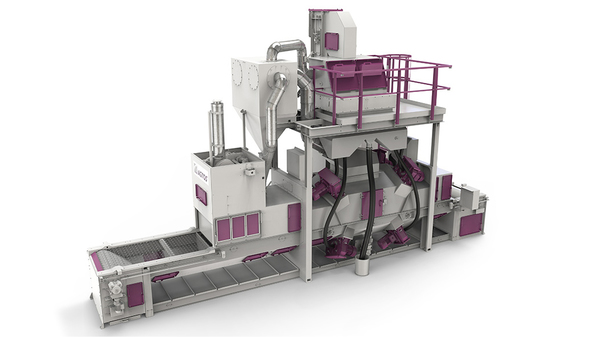

At this year's trade fair, the blasting system manufacturer AGTOS is presenting a very special machine. Visitors can see for themselves the high quality and advantages of a wire mesh conveyor shot blast machine. The blasting process is automated and therefore requires little manpower. In addition, the parts are processed simultaneously from above and below.

The topic of digitalisation is addressed in several ways. ‘Smart Monitoring’ uses data collected and collated during the production process to draw conclusions about the service requirements of the machines. This is illustrated by examples at the fair booth. When servicing is required, the AGTOS Service App can replace planned and time-delayed visits by service experts with real-time support.

Sustainable production is becoming increasingly important. The trade fair team will be using specific examples to demonstrate the high levels of consumption in individual processes.

AGTOS will also be exhibiting at this year's EUROBLECH together with its partner company SLF Oberflächentechnik GmbH. This means that all questions regarding blasting and painting can be answered on the spot.

The booth is located in Hall 26, Booth No. 24-L71. The AGTOS trade fair team is looking forward to your visit!

Further information is available on request.

Informationen zur Drahtgurt-Strahlanlage und zum Strahlprozess gibt es in diesem Video von der Euroblech 2024.

Das Thema Digitalisierung wird gleich mehrfach aufgegriffen. Beim „Smart Monitoring“ werden anhand von Daten, die während des Produktionsprozesses gesammelt und zusammengeführt werden, Rückschlüsse auf den Servicebedarf der Maschinen gezogen. Dies wird anhand von Beispielen am Messestand verdeutlicht. Im Servicefall kann die AGTOS Service App durch in-time-Betreuung geplante und zeitverzögerte Besuche von Servicefachleuten ersetzen.

Nachhaltiges Produzieren erhält stets größeres Gewicht. Daher zeigt das Messeteam anhand konkreter Beispiele auf, wie hoch die Verbräuche einzelner Prozesse sind.

AGTOS wird auch auf der diesjährigen EUROBLECH zusammen mit seinem Partnerunternehmen SLF Oberflächentechnik GmbH ausstellen. Damit können alle Fragen rund um das Strahlen und Lackieren direkt vor Ort geklärt werden.

Der Stand befindet sich in Halle 26, Stand Nr. 24-L71. Das AGTOS Messeteam freut sich auf Ihren Besuch!

Weitere Informationen erhalten Sie gern auf Anfrage.

AGTOS wire mesh conveyor shot blast machine for the cost-effective processing of a wide range of sheet metal parts.