Sustainability at AGTOS

The topic of sustainability has been with us for a long time. Our goal is to intensify these efforts even further. We accept our responsibility towards our employees and the environment. We are happy to inform our partners about our activities on this topic.

Principles of corporate social responsibility

Public welfare and civic engagement

The topic "Common good and civic engagement" looks at the relationship between the company and its social environment. This includes employees as well as the geographical region. Employee commitment, donation management and regional commitment are presented.

Corporate environmental protection

This topic area covers issues such as energy and climate, logistics, employee mobility and the environmentally friendly design of the site.

Workplace and employees

In addition to occupational safety and health promotion, this topic area also looks at training and development, equal opportunities and employee satisfaction.

Product responsibility

This fourth topic area deals with the ecological impact of products, digitalisation and data protection as well as environmental standards at suppliers, to name but a few.

Corporate Social Responsibility - Procedure at AGTOS

At AGTOS, the various CSR topics are dealt with by a team consisting of several employees. They come from the Purchasing, HR, Sales, Technology and Business Development departments. The CSR team is supported by the management.

Corporate Social Responsibility - Procedure at AGTOS

Measures implemented at AGTOS

Short-term measures

Measures were also defined that were to be implemented in the short term. This already included the improvement and consistent implementation of waste separation. Another measure concerned the introduction of free drinks for employees. Environmental aspects should also be taken into account here. High-quality purified water can therefore be obtained from a vending machine. Every employee has their own reusable vacuum flask so that PET bottles are no longer used. Furthermore, a fully automatic coffee machine for different types of coffee has been installed, a measure from the "Workplace and employees" area of action.

The most recent measure is the introduction of a bike leasing system for all employees and their partners. It is intended to promote health as well as satisfaction and support the switch to environmentally friendly mobility. Employee participation is good and the range of leased bikes is wide.

Employee with their new Jobbike

A newly launched internal newsletter informs all AGTOS employees about aspects relevant to the company, including CSR issues, and encourages them to actively support the company.

Medium-term measures at AGTOS

In addition to the measures that have already been initiated and implemented, we are continuously working on further activities. To this end, the CSR team meets at regular intervals. Measures that will be tackled in the future concern, for example, supplier management, customer satisfaction and other environmental aspects such as converting the hall lighting to LED.

Hall lighting at AGTOS with environmentally friendly LEDs

Everyone involved realises that a lot still needs to be done to become truly sustainable. But the first steps have been taken and small successes have become noticeable for everyone. Not every measure suits the company and priorities must also be adapted to reality.

The consultancy firm makes the following statement:

Sustainability at association level

AGTOS is a partner of the Blue Competence sustainability initiative. Blue Competence is an initiative of the VDMA, to promote sustainability in mechanical and plant engineering, but also to publicise sustainable solutions in the industry. With our partnership, we are committed to complying with the zwölf Nachhaltigkeitsleitsätze des Maschinen‐ und Anlagenbaus.

In April 2023 the VDMA magazine reported on AGTOS.

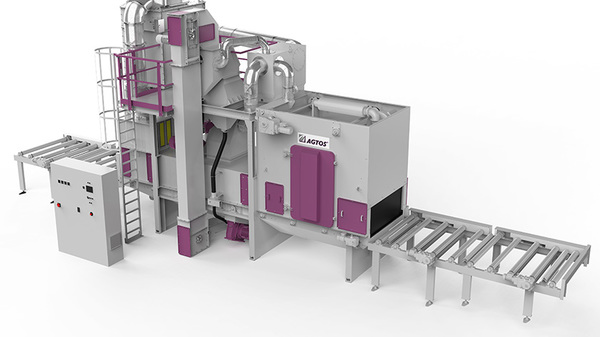

How the topic of sustainability is implemented in AGTOS product blasting systems.

Sustainability is already an important factor in the project planning of wheel blast machines. For example, simulations replace many time-consuming blasting tests that are associated with logistics and travelling. This benefits the environment.

Simulation of the blasting process

When planning and designing the machines, attention is paid to the most sustainable mode of operation possible. Automatic switch-off devices, optimised adjustment of the air separation (cleaning of the blasting medium), frequency converters for adjusting the drives to the process and differential pressure-dependent cleaning of the filter cartridges are just a few aspects. The use of IE4 class drives is being promoted. The most important aspects have been summarised in a leaflet that provides customers with comprehensive information.