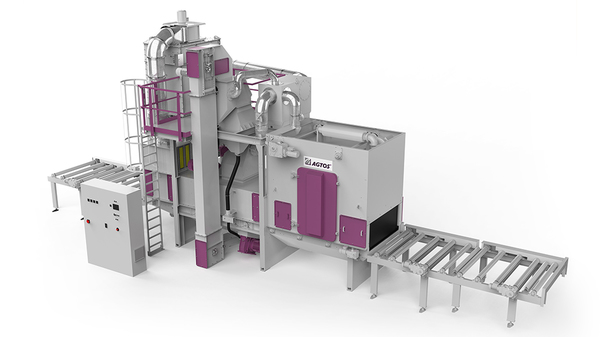

Roller conveyor blast machine

Roller conveyor blast machines are mainly used for descaling and derusting profiles and sheet metal. A roller conveyor system, combined with corresponding cross conveyor units, allows individual production stages such as blasting, preservation, sawing and drilling to be interlinked. This ensures a flexible production process and a high material output.

Another area of application for the roller conveyor blast machines is the blasting of structures. Here, the turbine arrangement and throughput opening are adapted to the geometrically demanding workpieces. Our advice also includes the choice of suitable blasting media.

Roller conveyor blast machines Product programme

Our standard roller conveyor blasting system programme includes throughput widths from 1000 mm to 3200 mm.

| Technical data |

RT 1000 4 x 11 |

RT 1500 4 x 11 |

RT 1500 4 x 15 |

RT 2100 4 x 15 |

RT 2600 6 x 15 |

RT 3200 6 x 15 |

RT 3200 8 x 15 |

|---|---|---|---|---|---|---|---|

| Primary application area |

Metal sheet Metal section |

Metal sheet Metal section |

Metal sheet Metal section |

Metal sheet Metal section |

Metal sheet Metal section |

Metal sheet Metal section |

Metal sheet Metal section |

| Workpiece size (mm) | 600 | 600 | 600 | 600 | 600 | 600 | 600 |

| Workpiece width (mm) | 1000 | 1500 | 1500 | 2100 | 2600 | 3200 | 3200 |

| Min. sheet thickness (mm) | 4 | 4 | 4 | 6 | 6 | 6 | 6 |

| Turbine type | 3.6.3 | 3.6.3 | 3.6.3 | 3.6.3 | 3.6.3 | 4.6 | 4.6 |

| Turbine performance (kW) | 4 x 11 | 4 x 11 | 4 x 15 | 4 x 15 | 6 x 15 | 6 x 15 | 8 x 15 |

| Max. Blasting speed round grain (m/min) | 2.2 | 1.5 | 2.0 | 1.4 | 1.8 | 1.4 | 1.9 |

| Abrasive flow per turbine (kg/min) | 181 | 181 | 248 | 248 | 248 | 165 | 165 |

| Filter | PF 4/12 | PF 4/20 | PF 4/28 | PF 4/28 | PF 4/40 | 2 x PF 4/28 | 2 x PF 4/32 |

| Performance (m3/h) | 4 500 | 7 500 | 10 000 | 10 000 | 15 000 | 20 000 | 24 000 |

| Overall filtering surface (m3) | 48 | 80 | 112 | 112 | 160 | 224 | 256 |

| Residual dust content in the exhaust air with secondary filter (mg/m3) | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

Surface treatment of metal: Polishing & matting metal

When a workpiece made of stainless steel or another metal is cast, forged or formed, it is still in its raw state. In order for it to fulfil its final purpose, further processing is necessary.