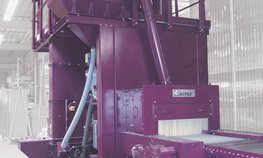

Concrete blast machine

These machines are also known as concrete shot blasting machines, as they are mainly used for processing paving and edge parts as well as concrete slabs and steps. The aim is to refine the surface of the workpieces. The mineral components of the concrete are removed by blasting. This gives the surface an elegant and valuable appearance.

The AGTOS product programme

Our standard program of concrete shot blast machines feature process widths from 600 mm to 1250 mm.

The choice of the appropriate machine concept depends on your work pieces, the required level of performance and last but not least on your specific needs regarding an optimized production process.

In the event that a standard model does not meet your surface preparation needs, we will develop a tailor-made blast machine concept for you.

Our team of experts welcomes your detailed questions and looks forward to helping you!

The operating sequence for belt blast machines

The concrete blocks, slabs or stairs are placed on the intake side of the conveyor belt with handling equipment. When released by the machine operator, the conveyor belt cycles one batch further at a pre-set transport speed, exposing the concrete work pieces in the blasting unit to the abrasive stream.

After blasting, a high-pressure blower with a height-adjustable nozzle blows off any abrasive still remaining on the work piece. The use of handling equipment during the load and unloading process ensures a flexible manufacturing process and high material output.

The entry and exit vestibules are sealed off with wear-resistant rubber curtains. After completing their passage through the blasting unit, the finished work pieces reach the exit area, where they are removed from the conveyor.

The blasting abrasive is continuously cleaned, recirculated and reused. An abrasive metering device feeds the cleaned abrasive from the abrasive storage bunker to the high-performance turbines.

A fan unit creates the partial vacuum necessary to maintain dust-free operation of the blasting unit. Extracted air is cleaned in a special filter unit.