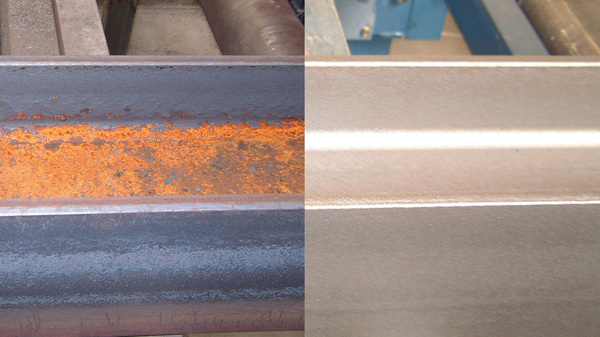

Removing rust: effective household remedies and industrial solutions

How does rust form?

Oxygen, which makes life possible in the first place, reacts directly with most other elements. If it comes into contact with iron, rust is formed in the presence of water: this is porous and does not protect the base material from further decomposition, so the iron reacts differently to other metallic materials such as chrome, aluminium or zinc; here the metal oxide forms a protective layer. For this reason, rust must be removed to protect objects with iron from further decomposition.

Chemically speaking, rust consists of iron(II) oxide, iron(III) oxide and water of crystallisation. During rusting, the solid, iron-containing material (e.g. steel) becomes a loose structure with low strength.

How can I remove rust stains as a private person?

There are basically two ways to remove rust. You can:

- remove the rust mechanically or

- transform the rust by means of a chemical reaction.

The first option is particularly suitable for localised rust spots if they are easily accessible. A variety of tools are available for the mechanical removal of rust. Depending on how much rust needs to be removed and what is available, you can use files, wire brushes, sandpaper, fibreglass rust removers, steel wool, angle grinders or wet sanding sponges. Plait brushes are also available as attachments for drills. And if you need to remove rust frequently, you can buy or hire a sandblasting machine from a hardware store.

Acid, rust remover or rust converter are suitable for chemical treatment. These products are available from hardware stores, among others. However, common household acids and cola are also suitable for an immersion bath. It is important to observe the process. As soon as rust is no longer visible, the workpieces must be thoroughly rinsed and the metal completely dried. Any remaining acid will attack the metal.

Treatment with rust converter, cola or phosphoric acid produces a black coating: iron phosphate. To be sure that there is no more rust under this black layer, it should also be thoroughly removed.

Another option for the chemical treatment of rust is electrolysis. However, as it involves working with an electric current and hydrogen is also produced, this method is only recommended for skilled persons.

What machine methods are available for derusting?

The basic principles for derusting on an industrial scale are often the same as in private households. However, completely different machines and plants are available, and other processes are also used. In addition, the initial condition of the surface and the results of the preparations for further processing are categorised into different grades. This makes it easier for the customer and service provider or supplier to communicate - it is clear to both sides what the initial situation is and what needs to be done.

To remove rust chemically, the workpieces can be pickled or phosphatised. However, suitable plants must be available for this. Mechanical processes also include grinding or brushing with the appropriate machines. Other options include laser cleaning and flame blasting as a thermal treatment.

Why is the removal of rust important for further processing?

If you compare the properties of iron with those of rust, it quickly becomes clear why rust is undesirable for two reasons:

- Rust that is not removed gradually transforms a solid, ferrous object into a loose structure. This disintegrates even under low loads and can not only render the object unusable, but also pose a danger - think of load-bearing parts in a car, for example.

- The volume of the ferrous material increases when it rusts. If the rust is not removed, the coating will eventually flake off. The rust layer itself can also flake off. This means that other parts of the base material are exposed to atmospheric oxygen without protection and rust even faster.

For these reasons, it is also important to remove the rust during the production process. After all, if the rust is only coated or incorporated into an assembly so that it is no longer visible, the corrosion process will still continue. This makes the product unusable more quickly than would be the case with normal use.

What should be borne in mind regarding the methods?

The method used to remove the rust must be appropriate for the rust formation and the workpiece. Both chemical and mechanical methods must not damage the workpiece. The dimensions of the parts must also be suitable for the processing equipment. For quick, occasional and minor rust removal, manual work with an angle grinder may seem like the ideal solution. But be careful: Machine work is always much more productive than manual work. That's why it can be interesting to call in a service provider for contract rust removal work.

Mechanical blasting should be emphasised among the industrial methods: Of all the rust removal methods, it is usually the most economical, especially wheel blasting. It can be used to process workpieces with different degrees of rust until the desired degree of preparation is achieved. With wheel blasting, even the highest degree of preparation, Sa 3, can be achieved from all rust grades. Contamination, deposits, corrosion, scale and paint are removed. However, chemicals cannot be completely removed. The shot blast plants enable continuous operation on accessible surfaces, for example plates, flat beams, cast or rolled steel products and, depending on the design, can also accommodate workpieces with larger dimensions. Last but not least, the workpieces can be deburred and the surface roughened in a single operation. The disadvantage, however, is that the process is not suitable for sensitive surfaces.

How can rust be prevented?

For rust to develop and spread, iron, oxygen and water must come together as an electrolyte. However, the air already contains oxygen and enough moisture to cause any unprotected piece of iron to rust. Therefore, precautions must be taken to prevent rust from forming in the first place. There are two main ways to do this:

- You shield the iron material from the surrounding air. This works either with a protective coating such as paint or, in buildings, with concrete.

- The ferrous material is provided with a sacrificial anode. This is a piece of less noble metal than iron, which the oxygen in the air attacks first. As long as the sacrificial anode is not completely decomposed, the ferrous material is protected.

Both coatings and sacrificial anodes must be renewed regularly to maintain the protection.