Economical blasting of sheet metal parts of various sizes

In addition to sheet metal panels and profiles, many companies also need smaller sheet metal parts, such as gussets and connecting sheets. These also need to be blasted to remove welding residues, rust and impurities, or to prepare for subsequent coating.

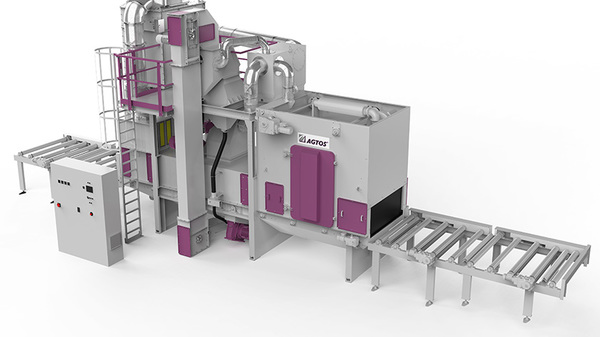

At this year's EUROBLECH trade fair, blast machine manufacturer AGTOS is therefore exhibiting a drum blast machine. One advantage of this machine type is the small "footprint" in the production hall, i.e. the compact design. Compared to other machine types, drum blast machines do not cause jamming and damage to the workpieces, even with small parts. The blasting process is automated and therefore requires less manpower.

In addition, concepts for the processing of large parts will of course also be shown. AGTOS roller conveyor shot blast machines offer many advantages in terms of economic operation and maintenance. The manufacturer of special systems will present various solutions for the processing of very heavy or large-dimensioned workpieces and constructions.

The topic of digitalisation will be addressed several times. On the basis of data collected and collated during the production process, conclusions can be drawn about the service requirements of the machines. This is illustrated by examples on the stand. In the event of service, the recently introduced AGTOS Service App can replace planned and time-delayed visits by service specialists by providing in-time support.

Sustainable production is becoming increasingly important. For this reason, the trade fair team uses concrete examples to show how high the consumption of individual processes is. In addition, there will be indications of where energy and costs can be saved in blasting technology.

AGTOS will also exhibit at this year's EUROBLECH together with its partner company SLF Oberflächentechnik GmbH. This means that all questions about blasting and painting can be clarified directly on site.